What is a Honing Tool & Single Pass Honing Tool

The purpose of the hone tool is to transmit the power generated by the machine to the work piece. Honing will correct the bore for taper, size, finish and straightness, but cannot normally correct axial alignment or location.

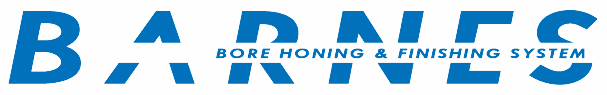

The tool consists of a spindle nose adaptor, a drive shaft, and the hone body. The hone body contains a cone attached to a push rod. See the drawing of a typical hone tool on the next page

The push rod, inside the drive shaft, is moved up or down in the hone body by a motor or hydraulic cylinder. The actuator is located in the head. As the conemoves down, it pushes the expansion plates outward, expanding the stones. The abrasive stones are used to remove the stock material from the work piece. The garter springs are used to keep the stones in the tool and to collapse the stones when the tool is removed from the bore.

The hone tools may use super-abrasives or vitrified stones for rough honing, semifinishing and final honing. Peak honing typically requires only the roughing operation. Plateau honing (putting a "plateau" on top) requires fine stones to remove the peaks. Some hone tools have both roughers and finishers in a single tool.

Hone Guides

The hone guides are part of the honing tool. They are used to protect the hone stones when entering or leaving the bore and prevent the metal of the hone tool from contacting the bore surface. The guides must be checked frequently for wear or pick up of foreign material. Honing stones are typically collapsed below the size of the guides when withdrawing to protect the stones and the hone guide bushing.

Hone Guide Bushing

The hone guide bushing is mounted to a fixed bracket on the front of the column. The function of the hone guide bushing. is to guide hone tool into the center of the bore. The bushing is typically made from hardened steel or carbide. Carbide is used when the hone guide bushing is also a "collapse bushing". These are used to force the stones back flush with the tool body when the tooling is too small to have garter springs.

Adjustable Cone

When honing blind bores, an adjustable cone may be used to expand the bottom of the stones to account for wear and to keep the bottom at size. Blind bore over travel shown above. Notice the stones cannot travel past the bottom as in through bores. This will cause uneven stone wear and a taper at the bottom of the part. The problem can be helped by the use of an adjustable cone and by the use of dwell at the bottom.

Single Pass Honing Tools

The hone tool may consists of a diamond abrasive boring bar which is constructed from an expandable soft cast iron sleeve permanently coated with 100/120 grit of natural diamond abrasive or it may be a sintered sleeve which has abrasive embedded in it. The tool is expandable, to compensate for diamond sleeve wear. The arbor contains passages for coolant flow to the grooves in the sleeve. The hone tool passes through the bore once and is withdrawn.

This machine uses a floating type hone tool that self-aligns with the existing bore. The tool is designed for honing open bores which have been generated by a previous machining. operation. The tool can correct a bore that is run-out, tapered and out-of-round conditions. The tool produces straight, round, un-tapered holes in one down stroke.

The hone guide bracket and bushings are mounted to a fixed bracket mounted to the front of the column. The function of the hone guide bracket is to guide the hone tool into the bore. The bushing is machined to allow coolant to flow to the single pass hone tool.

PRECISION SURFACING SOLUTIONS

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.

Visit SiteLapmaster Wolters

Founded in Chicago in 1948 as a manufacture of lapping and polishing machines for the mechanical seal market, Lapmaster has grown to a worldwide solution provider for more than 20 industries like precision optics and advanced materials.

Visit SiteELB-Schliff

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".

Visit Siteaba Grinding

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.

Visit SiteREFORM

REFORM Grinding Technology GmbH is specialized in the sales, development & production of grinding machines for various applications at its location in Aschaffenburg (Germany).

Visit SiteKEHREN

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.

Visit SiteMicron

Produced in Germany since 2009, MICRON machines are compact and dynamically rigid grinding machines especially designed for Creep Feed and Profile grinding. MICRON is an industry leader in grinding of Hydraulic components like stators, rotors and van pumps.

Visit SitePeter Wolters

Founded in Germany in 1804 by Mr. Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936. In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and special materials of Meyer Burger. Further Information can be found at www.precision-surface.ch

Visit Site